Dry Flocculant Mixing and Feeding Design Considerations

/in Equipment, Informative, Manufacturing, Mining/by Mainland Machinery LtdThis is a guest post by Bill Hancock, President of Zeroday Enterprises

Dry Flocculant Mixing and Feeding Design Considerations

Dry flocculant wetting, dissolving, mixing and solution feeding must be done under very specific controlled conditions that account for the flocculant’s unique physical and chemical characteristics. Failure to ensure proper polymer solution preparation and feeding can result in mix-feed system plugging and erratic operation, process control issues and wasted polymer.

Key flocculant characteristics that must be considered for proper flocculant mixing and use are summarized below:

1) Flocculant powders are hydroscopic. Storage and dry polymer feeding systems must ensure minimum air contact as the particles will adsorb moisture which initiates flocculant dissolution. Dissolving particles are very sticky and consequently will aggregate into larger pieces and chunks. These larger pieces and chunks dissolve slower and often can plug equipment causing mix system and even process operational disruptions.

2) Water wetted flocculant particles can aggregate into masses. Since flocculant particles dissolve proportionately to exposed surface area, particle aggregates that have stuck together result in significantly reduced dissolution rate during mixing. If the flocculant aggregates do not fully dissolve within the set system residence time, these partially flocculant masses will pass through the mix system and process unused. And possibly plug equipment. Note: flocculant particles/aggregates will hydrolyze throughout into a clear gel which refract light differently than water, these masses are called ‘fish eyes’ because can predominantly see the light refraction, not the mass itself.

3) It is very important to initially wet each flocculant particle. The mixing system must be designed in the first step of the mixing process to wet each particle individually and immediately, and subsequently ensure these wetted particles do not aggregate or agglomerate. There are two main mix system flocculant particle wetting categories.

- Augering flocculant particles into a funnel with plenty of water flowing in the funnel followed by some motive dispersive force to ensure any particles that might stick together will be pulled apart.

- The flocculant particles are air blown from an auger into a large diameter hose to the top of the mix tank where cascading water inside a tube wets the particles which enters the mix tank and impeller.

4) Flocculant dissolution time variable. Flocculants dissolve at different rates, primarily dependent on the following factors.

- Type of polymer charge

- Flocculant charge level

- Water temperature and chemistry

Required mix times can range from 30-90 minutes are designed into a mix system.

5) Flocculant solutions are viscous. Dissolved long chain flocculants introduce solution drag that is expressed as viscosity. The amount of viscosity is dependent on the flocculant charge, charge level, temperature, concentration and molecule chain length. More viscous solutions require more mixing power. To ensure the flocculant molecule chains are not broken, balancing the amount of power in mixing and the type of mixing are crucial for minimizing dissolved flocculant chain damage.

6) Low shear pumps must be used for flocculant solution transfer and feeding. The two more predominate low shear pump types are progressing and diaphragm. More specifically, examples of pumps that are acceptable include progressive cavity, peristaltic, gear, lobe and air operated diaphragm.

7) Flocculant solutions typically provide best performance at ≤ 0.1% concentrations. To optimize flocculant mixing system sizing, flocculant solutions are often designed to be mixed to 0.25-0.50% maximum concentration. Once dissolved, the flocculants will dilute readily with teed in water down stream of the flocculant feed pump to obtain the final target 0.1% concentration.

Flocculant mixing and feeding is not highly complex. But the unique flocculant characteristics accounted and designed into a mixing-feeding system to ensure optimum preparation and minimized consumption.

Bill Hancock is an internationally recognized expert in mineral processing technologies, technical marketing management and water treatment. Hancock founded and owns Zeroday Enterprises which supplies chemical mix-feed systems, LTM conductive slurry level monitoring probes, peristaltic hose and tube pumps, mixers and flocculant and coagulant chemicals. He also founded Argo Consulting—a technical and technical marketing consulting practice focused on providing mineral processing, water treatment and technical marketing consulting services to the mining industry.

Accurate Slurry and Pulp Level Measurement

/in Environmental, Informative, Mining/by Mainland Machinery LtdThis is a guest post by Bill Hancock, President of Zeroday Enterprises

Accurate Slurry and Pulp Level Measurement

Accurate Slurry and Pulp Level Measurement when there is a froth or foam on top of the flotation cell, mixing tank or sump can be challenging under many conditions. Reasons for pulp level monitoring and measurement include:

- Mechanical measuring devices such as float balls and ultrasonic targets can become covered with solids causing the device to hang up, become heavy and sit in the slurry deeper and/or the slide mechanism gets jammed and stuck preventing smooth operation.

- Slurry density (% solids) fluctuations cause float-ultrasonic and pressure differential devises to vary. Changing slurry apparent specific gravity will cause the float ball to ride higher or lower in the slurry even if the slurry level stays constant. Pressure differential devices, such as bubble tubes and pressure differential electronic sensors, measure based on slurry weight above the device so will provide proportional pulp level readings as slurry densities change.

- Basic froth mechanics, particularly in flotation cells, where bottom layers of the froth bed will be quite wet because fine bubbles coursing upward to the froth will push entrained slurry into the froth. As the fine bubbles coalesce into larger bubbles and rise to the top of the froth bed, this slurry drains back into the cell. When froth characteristics or operating conditions change, the amount of water and slurry in the bottom layers of the froth will vary and make proper froth-slurry interface depth measurement more problematic.

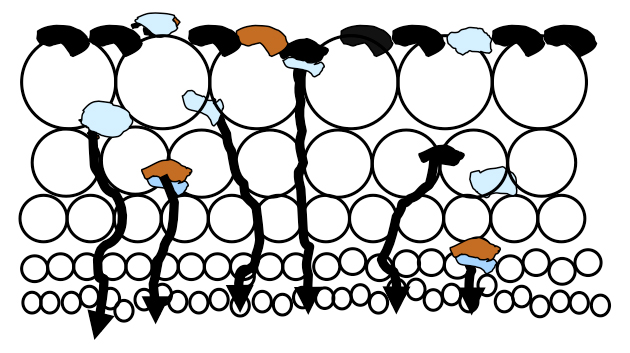

Point #3 is worth dwelling on because this is often overlooked or not well understood. A rough representation of a mineral flotation froth cross section is provided below. The fine bubbles generated by the flotation cell impeller rise to the bottom of the froth bed and coalesce into larger bubbles as these rise in the froth. The values are upgraded as the bubbles coalesce because the bubble surface area decreases with the result being less particle carrying capacity. Probabilistically the weakest, least hydrophobic particles are released and drain back into the cell.

There is a massive amount of air in a flotation cell, typically 12-25% of a float cell’s total volume, which rises enmass to the froth layer as fine bubbles. Much slurry is pushed into the lower froth bed which is held in the voids between the bubbles until the slurry can drain back into the cell. As illustrated in the figure, there is more slurry in the lower froth bed than higher due to drainage.

There is a massive amount of air in a flotation cell, typically 12-25% of a float cell’s total volume, which rises enmass to the froth layer as fine bubbles. Much slurry is pushed into the lower froth bed which is held in the voids between the bubbles until the slurry can drain back into the cell. As illustrated in the figure, there is more slurry in the lower froth bed than higher due to drainage.

This slurry in the void spaces between the bubbles must and will drain to the float cell. However there will be some slurry holdup before draining which can make the pulp-froth interface indistinct and difficult to define depending on the amount of slurry held in the froth. The amount of slurry carried into the froth can significantly vary.

Mechanical and pressure differential slurry level measuring techniques can have difficulties consistently and precisely monitoring the pulp-froth interface level under these conditions. However, electrical conductance pulp level measurement techniques can more effectively and consistently define the froth-pulp level interface height.

The conductive LTM pulp level monitoring probe technology dramatically reduces the complication of slurry level interface monitoring under a wide range of froth and flotation conditions. Because the probe is quite sensitive and measures at very low conductance levels, the probe capably and consistently measures at very low slurry (e.g. water) concentrations.

It is possible to define the slurry-froth interface level as the precise point where there is distinctly very low conductance due to a lack of slurry, at the depth where there is a predominance of air. In essence this is an electrical circuit on-off signal where the LTM pulp level monitoring probe identifies the depth where the froth is sufficiently drained preventing electrical current transmittance. From a logical reasoning standpoint this is a practical and effective measure. And is the slurry level interface level the LTM probe monitors.

Bill Hancock is an internationally recognized expert in mineral processing technologies, technical marketing management and water treatment. Hancock founded and owns Zeroday Enterprises which supplies chemical mix-feed systems, LTM conductive slurry level monitoring probes, peristaltic hose and tube pumps, mixers and flocculant and coagulant chemicals. He also founded Argo Consulting—a technical and technical marketing consulting practice focused on providing mineral processing, water treatment and technical marketing consulting services to the mining industry.

Check Out What We’re Doing in Prince Rupert!

/in Business Development, Canada, Company Update, Ports & Terminals/by Mainland Machinery LtdCheck Out What We’re Doing in Prince Rupert!

New Grain Container Stuffing Facility

Ray-Mont Logistics called Mainland when they wanted to complete a challenging and time sensitive project.

Ray-Mont Logistics is expanding and taking advantage of new transportation routes opening up in Prince Rupert. A new partnership between Ray-Mont Logistics, CN and the Port of Prince Rupert will see the development and building of a new grain container stuffing facility up and running for the 2017/2018 grain crop.

Located on Ridley Island, in the Road, Rail & Utility Corridor, it is the only unit train stuffing facility on Canada’s West Coast. A large endeavor for all involved, it will be capable of handling unit trains and pulse crops for container stuffing and forwarding to final destination.

We are very happy to be working alongside Ray-Mont on this entrepreneurial move to set up the first of it’s kind facility on the West Coast, and are looking forward to continued collaborating on the project.

This is a time sensitive project, with Engineering starting in February and the new facility to be commissioned in September.

We look forward to sharing more as the project advances!

Breakdown? Emergency Repair Needed? We Can Help!

/in Company Update, Services, Welding/by Mainland Machinery Ltd

INDUSTRIAL SERVICES AND EMERGENCY REPAIR WORK

Whether an unplanned shutdown, equipment breakdown, or you need a Millwright on site, you want repairs and work to move ahead in a timely manner with limited downtime. We all know the significant costs that are associated with extended downtime and plant closures – and we all want to avoid them. Even a planned shutdown is a risky process, and needs to be carefully planned for, and every possible situation taken into account.

In James R. Koelsch’s article How to Keep Shutdowns From Becoming Disasters, he touches on some very interesting points regarding “inability to recognize risks and the lack of systems specifically designed for startups”. Many are unprepared to deal with shutdowns and unexpected issues on larger scale, no matter how much is done to avoid them.

You may not have the internal man-power, technical knowledge, or time to try to solve the issue at hand. Thankfully, there are others who are well set up for such events and are at the ready to assist.

A well-versed, prepared Field and Industrial Services Team will have the safety qualifications, technical knowledge, and year of experience to ensure that whatever your issue at hand is will be dealt with promptly and properly.

With our dedicated Field Crew of Millwrights, Welders and Fabricators available at the ready, Mainland is here to help. Our field personnel have the latest safety certifications, have a wide range of industry experience, and are comfortable working in many industrial settings.

Don’t be caught off guard by an equipment breakdown or unforeseen shutdown; let Mainland’s Industrial Services Team help get you back up and running with minimal downtime.

To learn more about Mainland’s Industrial Services Team and the emergency repair solutions offered, check out the website, or give us a call. We would be glad to discuss preventative measures, provide an inspection report, or head out to help.

Industrial Services: Helping Your Next Project Succeed

/in Company Update, Services, Welding/by Mainland Machinery LtdHELPING YOUR NEXT PROJECT SUCCEED

Install, Maintenance & Overload Labour Services at the Ready

Did you know that Mainland offers a wide range of industrial services? Our team of Millwrights, Welders, Fabricators and Project Managers are at the ready to help your next project succeed.

Our field personnel have the latest safety certifications, have a wide range of industry experience, and are comfortable working in many industrial settings.

SERVICES PROVIDED

- Installation

- Millwrighting

- Maintenance

- Commissioning

- Overload Labour

- Plant Inspections

- Decommissioning

- Preventative Maintenance

- Equipment Repair & Service

- Troubleshooting & Maintenance

- Electrical/Control System Installation

- Emergency Breakdown Call Out Service

- Equipment Installation & Commissioning

- Civil/Structural Installation ie: Concrete, Formwork, Structural Steel

To learn more about our Industrial Service offerings, or to contact a member of our staff to make an appointment , visit the Industrial Services page.

Thickeners: How they Operate

/1 Comment/in Equipment, Informative, Technology/by Mainland Machinery LtdThis is a guest post by Bill Hancock, President of Zeroday Enterprises

Thickeners: How they Operate

The most common solids-liquid (S/L) unit operation is thickening. A wide variety of thickeners are used including conventional, deep well, paste, high rate and clarifiers which is a thickener subclass used for removing solids from turbid or very low % solids waters. Thickeners are mechanically continuous process equipment which operates on a particle/floccule sedimentation principle where in simplest terms the solids settle to the bottom of the thickener tank and the water overflows the tank.

Essential elements common to thickeners include:

a) Feedwell: where the slurry or water is introduced into the thickener which confines the kinetic energy of the incoming waters to minimize overall tank turbulence as well as directing the flow downward into the thickener

b) Rake mechanism: or similar device that pulls the settled solids/mud to the center of the tank; as the rakes travel through the mud, this plays an additional important role in disturbing the mud and releasing additional water retained by the settled mud

c) Under flow pump: which can be of several types including peristaltic, centrifugal, diaphragm and progressive cavity.

Thickeners are designed to operate continuously with slurry/water consistently flowing into the centerwell with thickener underflow pumping balanced to maintain a mud bed in the thickener. Key to thickener operational efficiency is the solids must be able to settle 2-4 times faster than the nominal water up flow rate. High feed solids recoveries reporting to the bottom of the thickener ensures high solids recovery and high overflow clarity levels.

Modern thickeners are designed based on use of highly effective synthetic (polyacrylamide) flocculants, ensuring high solids capture and adequate settling rates. Coagulants are sometimes also used when fine particle recovery is a challenge with flocculants alone. Fine particle recovery is needed to maximize thickener overflow clarity, minimize sands-slime separation in the bed which causes torque issues and to ensure bed solids flowability. Additionally coagulants can have positive downstream operational benefits such as in filters.

Flocculants are typically introduced either to the slurry-water pipe feeding the thickener, to a feed tank before the thickener, to the centerwell or a combination of these addition points. Where flocculant is optimally dosed is typically determined by plant evaluation and varies from operation to operation and is influenced by solids substrate, particle sizes and system specific factors. If coagulants are used, typically these are dosed upsteam of the flocculant addition point; however, in mineral concentrates, most often the best response is dosing coagulant after the flocculant.

Settled solids at the bottom of the thickener is called ‘mud’. The goal is to maximize the % solids in the underflow to recover as much water as possible for reuse. Primary means for controlling % solids is by mud depth and flocculant dosage. Deeper mud depths increase % solids because mud weight will cause more water to be released. Higher flocculant dosages, within a normal dosage rate range, will result in higher % solids. The % solids is typically limited by the thickener’s ability to transfer mud from the thickener and pumping the underflow because viscosity and slurry density increases dramatically with increasing % solids.

The simple animation below that shows only flocculant addition (not coagulant) illustrates these thickener operational principles.

Bill Hancock is an internationally recognized expert in mineral processing technologies, technical marketing management and water treatment. Hancock founded and owns Zeroday Enterprises which supplies chemical mix-feed systems, LTM conductive slurry level monitoring probes, peristaltic hose and tube pumps, mixers and flocculant and coagulant chemicals. He also founded Argo Consulting—a technical and technical marketing consulting practice focused on providing mineral processing, water treatment and technical marketing consulting services to the mining industry.

Flocculants: How Do They Work and Why?

/in Environmental, Informative, Technology/by Mainland Machinery LtdThis is a guest post by Bill Hancock, President of Zeroday Enterprises

How Do Flocculants Work and Why?

Have you ever wondered how flocculants work at the colloid (small particle) level?

Flocculants enhance, and are often required to make possible solid-liquid separations from turbid to high percent solids in water. Typically, solid particle sizes in water have a wide normal distribution and are inorganic and organic based. If these particles are denser than water, the particles will settle to the bottom of a container if given sufficient time; however, many of the smaller, lighter particles remain suspended (think a cloudy mud puddle that appears to swirl with activity) for a much longer time than allowed with a typical residence time. That is because the particles, or colloids, are small enough to remain suspended by external forces including Brownian motion (interaction with the water molecules), thermal currents, dispersive surface charges and the like. These are the hardest particles to treat because they are so fine and do not easily and quickly settle.

Unless the particles are uniformly coarse (depending on the water chemistry conditions and relative solid and water densities, coarse particles might be considered greater than 100 mesh or greater than 210 microns) and rapidly settle by gravity, flocculants are required to aggregate multiple particles together as ‘floccules’ which are pseudo-large particles. Enter the flocculants!

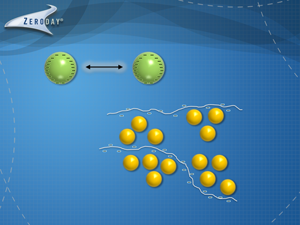

Polymers are ubiquitous materials ranging from nylon, polyethylene plastics, Teflon, and starches to amino acids. Flocculants belong to the water soluble polymer class, and so they fully dissolve in water. These are acrylamide based with functionality groups which allow the polymers to readily chemically adsorb to particles. These polymers are very long (for perspective, if you expanded a flocculant molecule to 1 inch in diameter, the total length would be on the order of 1.25 miles long!) As flocculant molecules dissolve in water, these molecular chains (ropes) are free to uncoil and expand, but are never completely linear due to random Brownian motion and water thermal current effects.

In effect, these flocculant ropes lasso aggregates of particles together. Since the polymer chains are very long, these polymers agglomerate multiple colloidal and coarse particles together. As these flocculated aggregates continue to mix, the polymer rope continues pulling the particle aggregate into a tighter and denser floccule, which causes the particles to settle more readily. The larger floccules are more easily filtered, centrifuged and floated in a dissolved air flotation unit.

A simple visual demonstration of this process is represented in the accompanying animation video. The animation shows the initial step of ‘coagulation’ where a short cationic (positive) charged polymer coagulant is added to partially neutralize the repulsive particle negative charges and induces pin flocc aggregation of the colloidal particles. Then the flocculant molecules ‘lasso’ and flocculate these pin floccs into larger floccules.

Bill Hancock is an internationally recognized expert in mineral processing technologies, technical marketing management and water treatment. Hancock founded and owns Zeroday Enterprises which supplies chemical mix-feed systems, LTM conductive slurry level monitoring probes, peristaltic hose and tube pumps, mixers and flocculant and coagulant chemicals. He also founded Argo Consulting—a technical and technical marketing consulting practice focused on providing mineral processing, water treatment and technical marketing consulting services to the mining industry.

Abbotsford Toys for Tots Christmas Breakfast

/in Charitable, Company Update, In the Community/by Mainland Machinery LtdAbbotsford Toys for Tots

We are excited to again be one of the many sponsors helping with the Abbotsford Toys for Tots Christmas Breakfast. This is an amazing event that has a direct and positive impact on our community, and we are glad to be a part of it! Stop by with a donation and enjoy the great breakfast buffet. We look forward to celebrating the start of this year’s Christmas season!

This year marks the fourth year that the Abbotsford Food Bank’s Christmas Bureau has partnered with the community to put on this great event. Last year was a record turnout with the most donations seen to date! 1300 toys and over $26,000 were donated. What wonderful things can happen when a community comes together. This year, let’s rally together and beat those numbers!

Come join us this Friday, November 25 from 6am-9:30am. Enjoy some great food, entertainment, and great conversation.

Stop by with a cash or toy donation and enjoy the great breakfast buffet. We hope to see you there!

Exciting New Partnership with Zeroday Enterprises

/in Business Development, Canada, Company Update, Equipment, International, Manufacturing/by Mainland Machinery LtdAnnouncing New Partnership with Zeroday Enterprises

Mainland Machinery Ltd and Zeroday Enterprises LLC are pleased to announce a partnership to advance Zeroday’s chemical mixing and feeding technology. As of August 9, 2016 Mainland has been named the exclusive distributor and manufacturer of Zeroday’s Z ChemGear product line of flocculant, chemical and regeant mixing and feeding systems!

Zeroday is an industry technology leader in process, water and wastewater treatment, and brings extensive chemical knowledge and experience used in designing quality, effective and robust chemical mixing-feeding systems. Mainland has over 45 years of value added manufacturing and engineering experience with involvement in diverse industries such as mining, oil & gas, municipal infrastructure, industrial agriculture and ports & terminals. The mutually supportive skills and core capabilities of each partner will enhance business competitiveness, capabilities and product line strength.

With locations in Wilsonville, Oregon and Abbotsford, B.C., we will continue to sell and support systems globally through EPCM, third party vendors and directly to customers. Canadian sourcing is expected to make the mix-feed systems much more competitive.

Zeroday’s Principal, Bill Hancock, is internationally recognized for his expertise in mineral processing technology and water treatment, and holds patents in flocculation and flotation applications. Bill will be involved in product line, sales and technical support, as well as independently promoting product line sales.

Mainland is pleased to be working alongside Zeroday Enterprises to produce innovative and cutting edge technologies! And Zeroday is excited about partnering with Mainland who will provide greater engineering and fabrication resources and expertise.

To inquire about products to meet your floc system neeeds, please contact sales@mainlandmachinery.com

To learn more about Zeroday, see their website

Contact

#110 – 2125 Windsor Street

Abbotsford, B.C.

V2T 6L9

Shipping Address:

#110 – 2138 Carpenter Street

Abbotsford, B.C.

V2T 6B4

Phone: 604-854-4244

Fax: 604-850-1796